Ecoserv, acting in a consortium with EcoTechnologia based in Jędrzejów, 2020, reconstructed the flue gas treatment system for two boilers: WR 25/14m No. K1 and K2 and WR 25/40m No. K3 at the “Dąbska” District Heating Plant in Szczecin.

The net contract amount was approx. PLN 5,200,000, including Ecoserv’s scope of approx. PLN 3,000,000.

The investment aimed to modernise the flue gas dedusting system for the modernised WR25 boilers, as a result of which the dust concentration in the entire operating range of the boiler would not exceed 50 mg/Nm3, and to enable the future construction of a dry method sulphur reduction system.

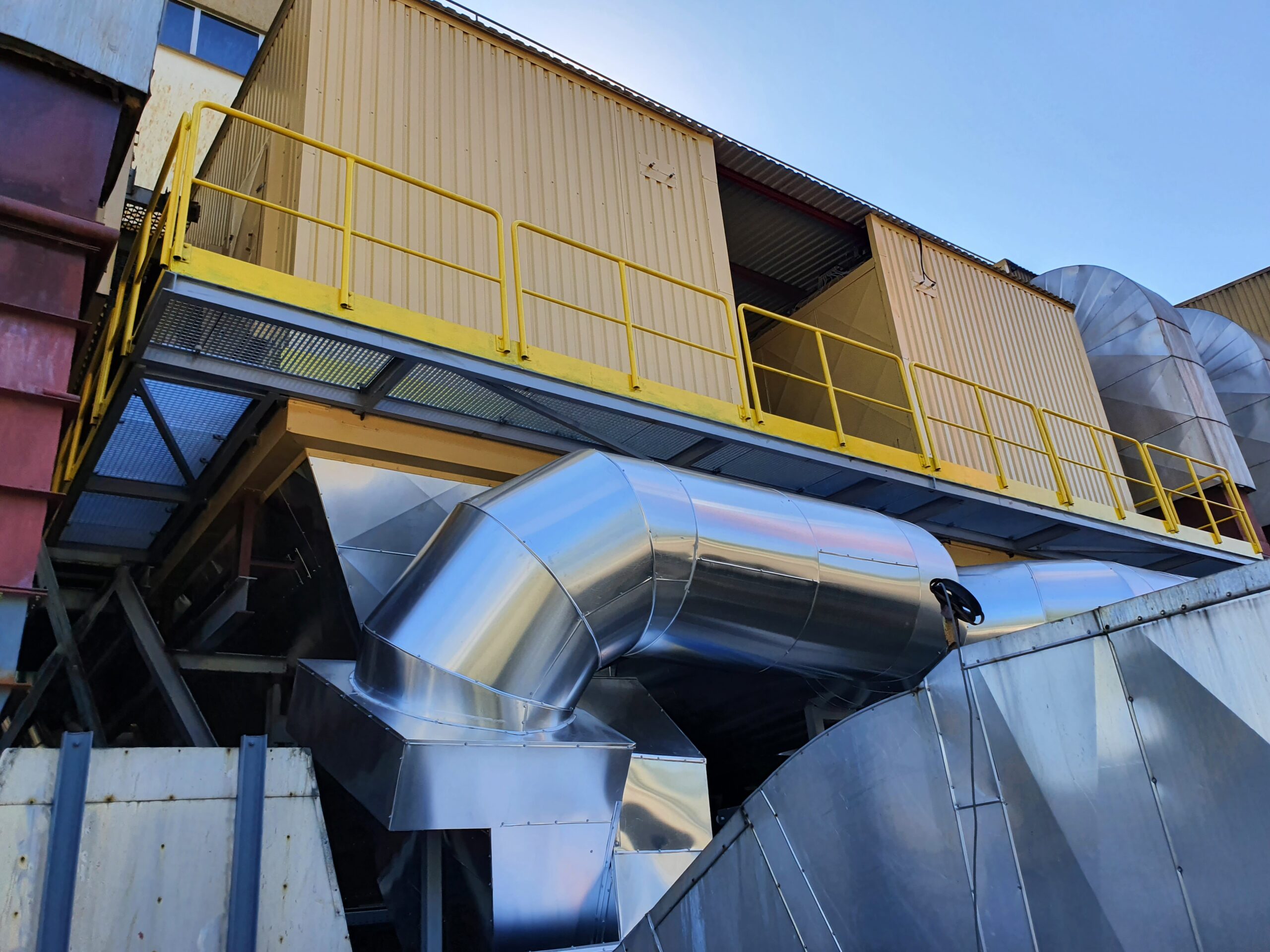

The system was modernised by installing bag filters in a horizontal arrangement with a capacity of 43,000 m3/h for K1 and K2 boilers and 108,000 m3/h for K3 boiler, respectively.

Scope of works:

- Preparation of documentation for modernisation of the dedusting system.

- Obtaining administrative approvals, including a construction permit.

- Repairing the existing foundations.

- Supply of FP 4×134/3.0/871 bag filters for K1 and K2 boilers and two FP 5×132/3.0/1086 filters for K3 boiler in a horizontal arrangement.

- Supply and assembly of flue gas ducts for exhaust fans.

- Supply and assembly of exhaust fans.

- Supply and assembly of the dust collection system.

- Participation in start-up, training, final acceptance, and commissioning of the dedusting systems.