Ecoserv, acting in co-operation with EcoTechnologia, carried out the “Modernisation of WR-25 boilers No. 1 and No. 2 at ZP3 Mysłowice and WR-25 boiler No. 6 at ZP13 Szopienice in 2021 – 2023. This was done to adapt them to and meet the requirements of the MCP Directive”.

The works related to the investment were carried out based on a contract concluded in August 2021 and ended with the commissioning of the investment in May 2023.

The net contract amount was approx. PLN 4,500,000.

Scope of works:

K1 boiler (WR-12 – 12.5MWt) and K2 boiler (WR-12 – 12.5MWt) – ZP3 Mysłowice

- Modernisation of the existing dedusting plant, consisting in its adaptation to the reduced capacity of K1 and K2 boilers, including:

– execution of the modernisation project

– replacement of the flue gas exhaust fan

– replacement of bags, blowpipes, and nozzles, sealing off part of the holes left by the dismantled hoppers (K1 boiler),

– adjustment of flue gas ducts at fan inlet and outlet (K1),

– complete bag filter (K2 boiler),

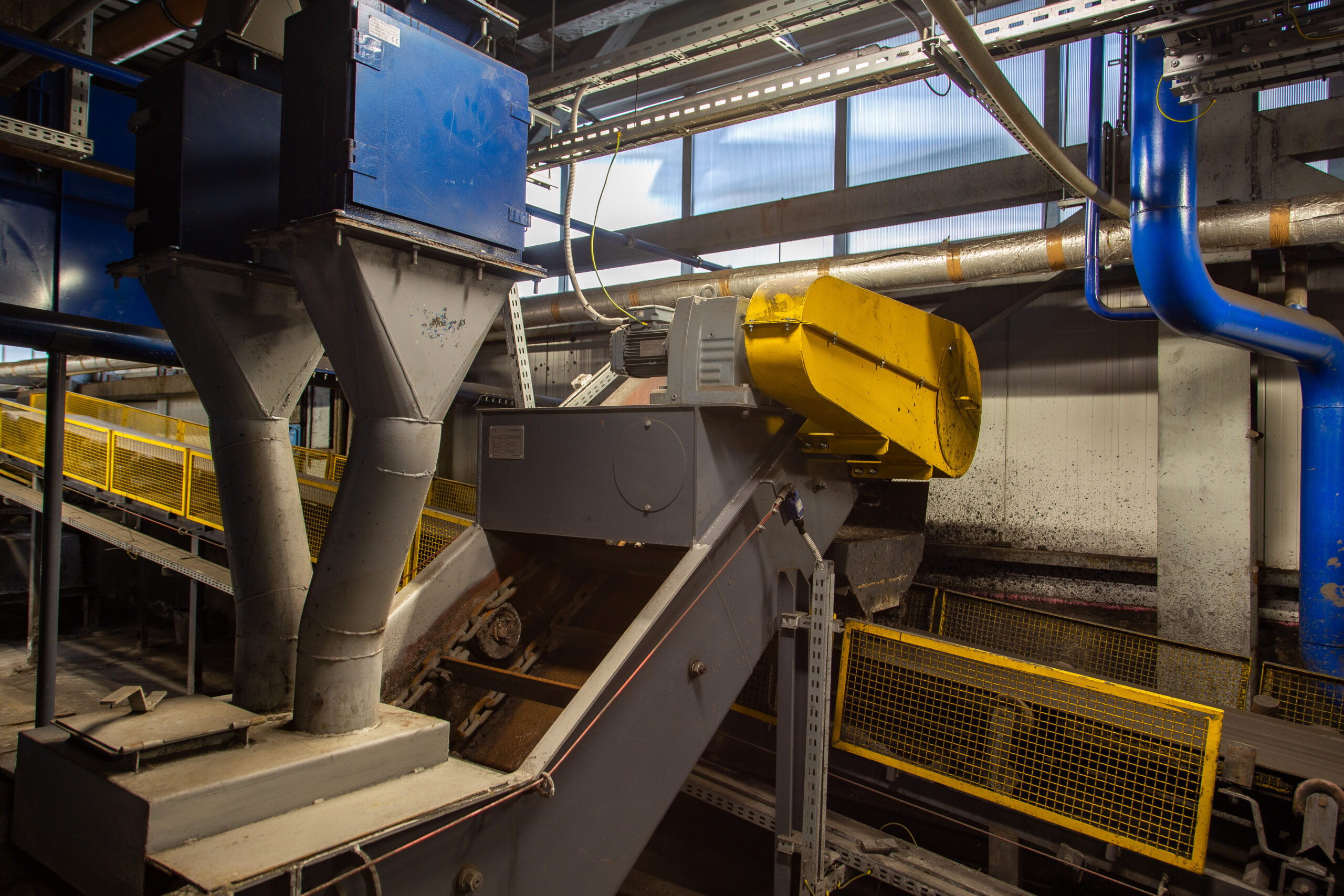

– screw conveyor (K2 boiler),

– dampers (K2 boiler),

– exhaust fan (K2),

– supporting structures, ducts, and service platforms.

- Preparation of a technical design of grates and a slag trap.

- Prefabrication, delivery, and assembly of the supplied equipment and components for the modernised dedusting system, grates, and slag traps.

- Adjustment and test run.

K6 boiler (WR-25 – 29MWt) – ZP13 Szopienice

- Preparation of design documentation for dedusting (including detailed designs).

- Prefabrication and deliveries, including:

– a multi-cyclone,

– a complete bag filter,

– a screw conveyor

– dampers,

– an exhaust fan,

– supporting structures, ducts, and service platforms. - Complete assembly of the dedusting system.

- Preparation of a technical design of the grate and the furnace waste discharge system.

- Prefabrication, delivery, and assembly of the grate and the furnace waste discharge system.

- Adjustment and test run.