Ecoserv, acting in a consortium with Sawox from Kielce, carried out an investment for MEC in Ostrowiec Świętokrzyski consisting in the construction of a combined flue gas dedusting and desulphurisation system. This was done using the dry method with simultaneous reduction of nitrogen oxides using primary methods, for two WR-25 boilers with a capacity of 30 MW. The works were carried out on the basis of two separate contracts for the WR25 K6 and WR 25 K5 boilers in 2019/2022. The total net contract amount was approximately PLN 14,500,000, of which Ecoserv’s scope was approximately PLN 6,600,000.

The systems were built on two coal-fired WR 25 boilers.

The desulphurisation systems based on dry sorption with the use of calcium or sodium sorbents and the denitrification system ensure the reduction of sulphur concentration in flue gas below the assumed contractual values, i.e., 400 mg/Nm3, dust below 10 mg/Nm3 and nitrogen below 250 mg/Nm3.

Scope of works:

- Preparation of FGTS design documentation.

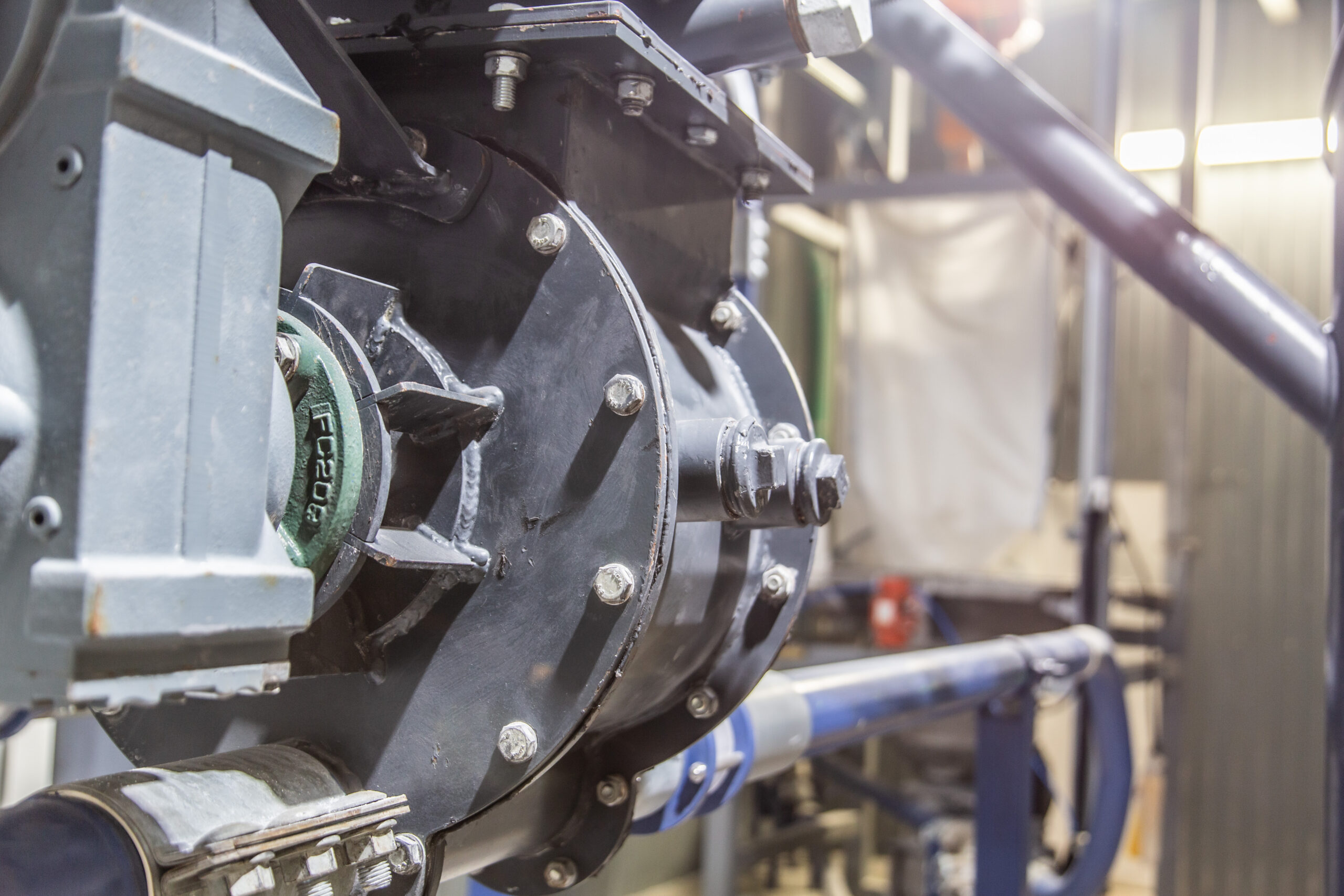

- Delivery and assembly of denitrification system components, including the RTWK 2×2.5×7 grate together with the reversible trolley and air-blowing system.

- Delivery of a complete dedusting system based on a bag filter.

- Supply and assembly of process equipment, including supply and assembly of a sorbent silo with a support structure.

- Supply and assembly of peripheral equipment, including supply and assembly of sorbent dosing system.

- Participation in commissioning, training, and final acceptance of systems.